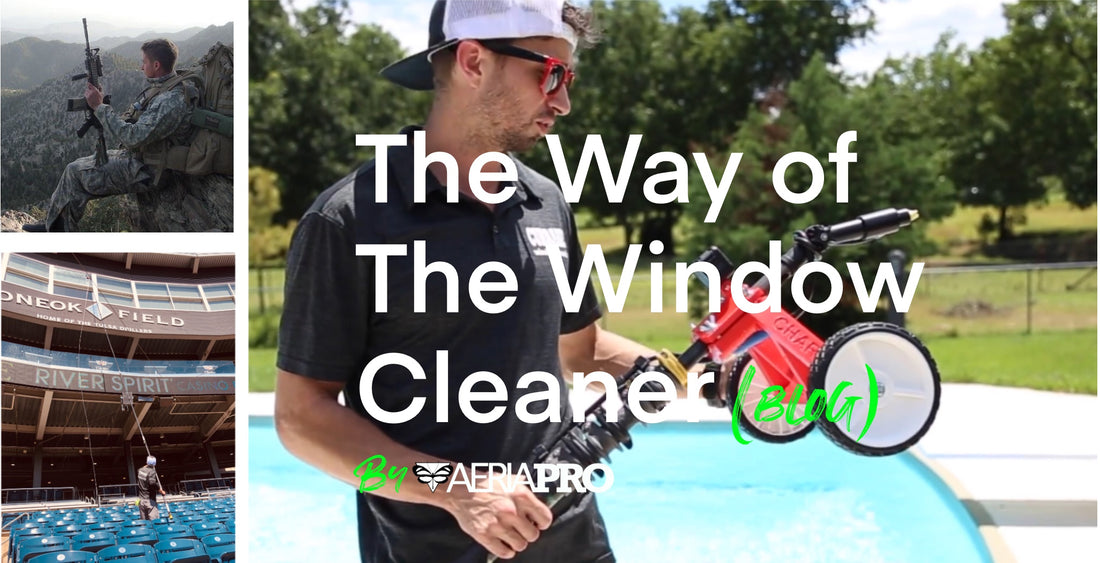

If you haven’t heard of the “Chariot”, Bucket Buddy, or the Mo Flo, then you haven’t been paying attention. These products from C3D Solution seem to have sprung up out of nowhere and seem to be everywhere. It feels like every other window cleaner is using one of these tools and the industry has embraced them. So, I couldn’t pass up the opportunity to interview the founder. I wanted to understand Brent and Landin’s rise from window cleaning to product design. But before we jump into the interview, let’s get to know Brent a little better. He is a father of two young boys, a husband, a man of faith, and an Afghanistan Vet. Brent served in the 101st Airborne, out of fort Campbell.

Brent...” I served 3.5 years total, 2.5 years of them in Garrison and 1 year in Afghanistan. My contract was 4 years, but I did what's called early separation for further education. Meaning I got out early, so I could go start college.”

Aeria Pro — Ok Brent, here we go. Let’s start with where you are from. Tell us about your place in the world, what is the area like?

Brent — I live in Claremore, Oklahoma which is about 20 minutes from Tulsa. It's a smaller city but, right in the middle of city and country life. If you go West for 10 minutes, you’re in a populated city. If you go east 10 minutes you’re in open cattle ranches.

Aeria Pro — I would guess being 20 minutes from a major city like Tulsa is a good thing. I imagine you are servicing a lot of the surrounding suburbs?

Brent — Yes. In Oklahoma, houses are strictly once a year unless you get higher end clients. We did a lot of houses in our direct area and dominated commercially. But when we started 3D printing, we slowly converted to strictly commercial.

Aeria Pro — How is the weather? What do your seasons look like?

Brent — The weather is all over the place. On Christmas it was around 60 degrees and, a couple of days later, it was in the 20s. Winter season we don't get a lot of snow, mainly ice. Summers can be brutal. We have very high humidity and average around 103 + heat index in the summer. We have short Fall and Spring seasons. This Spring we had record flooding and over 100 tornadoes touch down in Oklahoma. It was wild. We strictly do our large commercial work in winter.

Aeria Pro — Wow over 100 tornadoes...that’s crazy! I guess that would put a damper on your work day. It is quite amazing for me to hear what environments and conditions other window cleaners have to work with.

Aeria Pro —Let’s change gears a little bit and talk about your journey. How did you go from being a Screaming Eagle (nickname of the 101st Airborne) to window cleaning? What did that look like?

Brent — I actually did window cleaning as my summer job when I was 14 with my best friend's dad. We only did old-school cleaning with Ettore backflips and paper towels for touch ups. After I got out of the army, I had another business but didn't feel like I had complete control over it. I always went back to window cleaning for quick cash when my wife and I got tight on money. So I decided to make a very corporate feeling professional window cleaning business. Most cleaners in my direct area are bucket bobs with no insurance. My goal was low rise commercial and houses. We rarely do route work just because there's plenty of people in my area that have hamstrung the route work.

Aeria Pro — What about the product side of things, how did you get started doing that?

Brent — It all started with our Bucket Buddy which is the wand wring out tool. Landin (my business partner) and I were at a post construction job during the winter. I have some cold weather injuries in my hands from Afghanistan and my hands get cold very easily. We had been talking about 3d printing just messing around with what it could do. Finally, we started talking about a product that mimicked a hand shape that could wring the excess water out of a wand without using our hands. Or could be useful if there were chemicals you didn't want to get on your hands. I drew up a basic concept and Landin designed it in CAD. He is going to school for electrical engineering, so he had experience with CAD software. So we designed it, and we bought the cheapest 3D printer we could find. Printed the bucket buddy and it went from there. We really try to focus not on “good selling” products but problem solving products.

Aeria Pro — Tell me about your partner Landin, what is his role?

Brent — Landin does ALL the design work and print logistics. He is also studying electrical engineering and has done an internship with a sister robotics company Bill Gates owns.

Aeria Pro — How do you guys come up with your product ideas? Does it just hit you one day or do you try and look for problems to solve?

Brent — We really get our main inspiration from issues we encounter in the field or from other window cleaners. My best friend owns a window cleaning company, I also have a good relation with some bigger window cleaning companies in our area. Other than that, suppliers or window cleaners send us issues they need help with.

Aeria Pro — I see you guys just got a new printer, it looks like it is a game changer. Can you talk about it?

Brent — This new printer is the biggest step we've ever taken. It's a whole different technology than all our other ones and it costs more than all of them combined. It uses a laser to sinter powered nylon. Basically, fusing it together, one small layer at a time. The result is a very accurate part which is also very durable since it's nylon. It's so accurate you can even print movable parts within the print in one go. For instance, you could print a suspension model of a car and print the A arms and the suspension spring all in one print without joining anything.

Aeria Pro — You must be very busy these days between C3D Solutions and window cleaning. Do you have a hard time managing it all? What are some of the things you do to stay on top of things? Do you have any tips that may help other guys trying to run their businesses and other things?

Brent — It gets very hectic especially when Landin is in school. We have had to cut back on some of the window cleaning jobs to the ones that are most cost effective. Since both sides of the business share the same busy season, it gets crazy. So we've decided to focus on routine small to medium commercial jobs. We use Google sheets and Google calendar for our scheduling. A lot of the customers have events or specific days they want things done. We are learning that having a system is the key. Your business can only grow as much as your systems allow it, otherwise growth will kill you.

Aeria Pro — How has the covid crisis effected your window cleaning business?

Brent — Window cleaning only partially, we decided to hold off on more jobs than we were told to not do. Primarily because we do a lot of commercial window cleaning with hospitals, during April, they weren't allowing any personnel on that weren't directly related to the hospital.

Aeria Pro — How has it effected the product business?

Brent — For printing side we only had a minor delay but really the orders kept coming. The only change was getting our hands on material. The biggest issue we've had were getting spray nozzles. We couldn't import any spray nozzles, so, we began to make our own. We're firm believers that behind every problem is an opportunity. You would be surprised from a design standpoint, how hard it is to make water do what you want it to do. After we figured the proper design, flow, and angle we wanted, we integrated that into our prints. This allows the nozzles to be printed all together, greatly reduce printing time and material used.

Aeria Pro — What sets your products apart from your competitors?

Brent — Well, as far as 3d printing in the window cleaning industry, we don't really have any competition YET. We have caught some people trying to copy our designs. We're all about IMPROVING products or ideas, but copying other people and rebranding is just lazy. Now as far as injection mold goes, 3d printing has a lot of pros and cons. First the pros...It's very easy to change design and make a new product. We literally have made products and designs and had the prototype in hand same day. The startup cost is so much lower because a mold is going to cost you at least $5k. Third, you can print very complicated geometrys that you can't make through injection molding. Lastly, a wide range of materials. 3D printing you can print in plastics, wood, metals, carbon fiber, resin powder. Injection molding can prodvide more rigid parts and obviously can produce items a lot faster overall than 3d printing. But again, with 3D printing there's no MOQ on orders really. Most manufacturers are going to require at least 1000 units per order.

Aeria Pro —Well Brent it has been a real pleasure getting to know you better. I just want to thank you for taking time out of your busy life to talk with me and share what you do. Also thank you for serving our country. I wish you and Landin the best and hope C3D Solution continues to be successful.